If you like to tinker with electronics, you have probably heard of printed circuit boards. They are the building blocks of modern electronics.

Basically, everything we use, from computers to phones to TV’s contains at least one of these. And while a printed circuit board is customizable as it is, hobbyists haven’t been able to make their own. Until now.

With the rise of 3D printing, the home-based tinkerer can design and manufacture custom objects using a 3D printer. You can even use them for circuit printing.

There have been many other ways of making printed circuit boards at home over the last few years. But this may be one of the easiest and most affordable methods of printing circuit boards.

Wondering why printed circuit boards are important? Want to know how you can start making them yourself? Keep reading to learn all about DIY circuit printing.

What Are Printed Circuit Boards?

A printed circuit board is the current standard for programming electronics. A board can be made up of a single layer board for simple applications, such as a garage door opener telling the door to open or close.

Some electronics, such as a smartwatch, can have a 6 layer circuit board for performing complex functions. Computers and other forms of technology can often have many more layers.

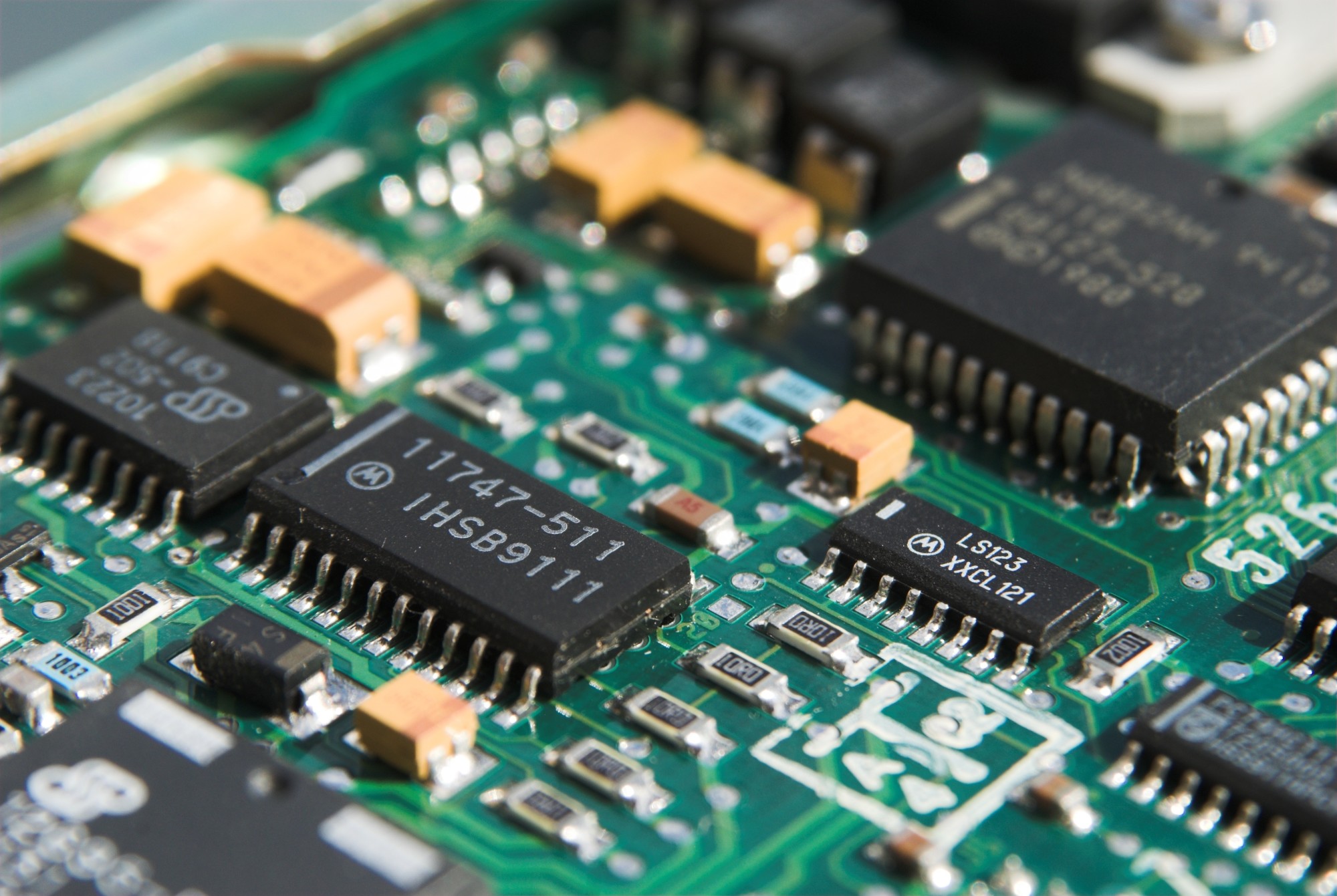

The individual layers of a circuit board contain many components that are connected together by conductive circuits made of copper. These components, such as semiconductors, resistors, diodes, and more, send electrical signals to each other to communicate.

In the past, electronics were hand-wired. Today, printed circuit boards, or PCBs, are just that; printed. Large machines are able to make these much more efficiently which makes electronics plentiful and affordable.

How to Print a Circuit Board

Most printed circuit boards are custom-designed for a specific use and product. There isn’t a one-size-fits-all type of circuit board.

When hobbyists or designers want to test new products and ideas, it helps to be able to design a new circuit board. In the past, the only option was to either etch a board by hand or hire a circuit printing company.

Today, there are a number of ways to produce a custom board. Using a 3D printer, you can quickly produce an experimental circuit board.

The printer is used to create the maze-like board itself. Then you can add the components and fill the channels with a conductive material, such as conductive paint.

You should have a working circuit board, however, it might be more fragile than a soldered board. Reflowing solder can be used to attach the components to the contact pad for a more durable, vibration resistant circuit board.

Circuit Printing Is More Fun

Sure, you can come up with a circuit board design and send it into a commercial printer to have them produce the board for you, but where’s the fun in that?

If you have one specific design you need, that might be a better way. But if you are experimenting with different designs and want to try new things quickly, 3D circuit printing is a better option.

It gives you more flexibility and will save you money if you try a lot of different designs. Looking for additional tips and tricks on bringing your next project to life? Be sure to visit our blog for more.