Pallet inverters’ primary function is to turn and move paper and cardboard pallets of various sizes, weights, and formats. The pile is raised and turned hydraulically to accomplish this.

They reverse the product to eliminate time-consuming manual handling. The pallet would then be manually removed from the equipment and a new pallet is added.

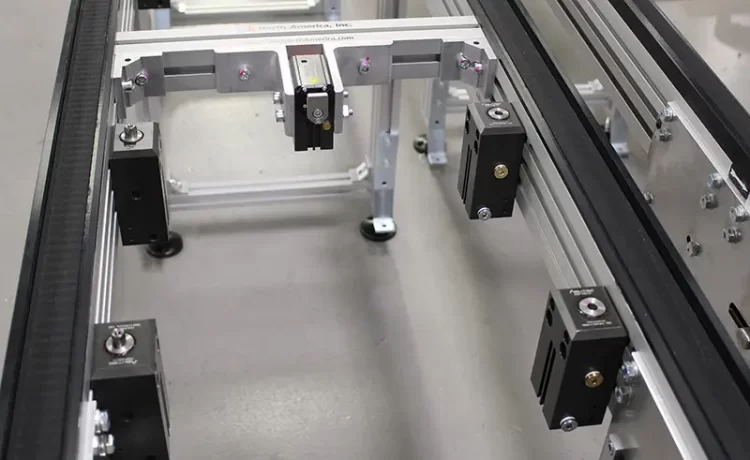

Top Industries Inc. has been a leader in this sector for many years and can design a suitablepallet inverter for any industry or warehouse based on the process of the operation.

Pallet inverter basic uses

While the precise uses of pallet inverters may vary based on the type of industry, a few basic uses of these pallet inverters are:

- To remove damaged products lying at the bottom of any pallet load.

- Removed and replace any damaged pallets.

- An exchange between wooden and plastic pallets.

- To invert/rotate your product to store properly

Few reasons why pallet inverters are used in the packaging industry

All three industries—packaging, printing, and cardboard conversion—are seeing rapid growth, and they all hope for faster and better results. Pallet inverters have proven to be an excellent investment because they can:

- Speed up and improve your printing quality and the finishing process

- Handle different kinds of paper and board

- Increase safety and productivity

- Provide a compact and solid solution

- Avoid any mis-feeds by creating a certain air cushion between the sheets

Pallet inverter applications

Any company that keeps merchandise on pallets can use pallet inverters. Pallet inverters are an excellent choice if you want to decrease the rate of product damage, switch out pallet types, or just increase the efficiency of your business. The following list of specific applications for pallet inverters in various industries:

· Pallet transfer

The majority of food products are sent on wooden pallets, but before they can be kept in production areas or clean rooms where sanitation is a top priority, they frequently need to be switched to plastic pallets.

Pallet inverters make it simple to switch out wooden pallets for plastic ones. Even if food products are stored on wooden pallets, product spills or leaks may necessitate pallet replacement.

Using a pallet inverter instead of doing it manually makes this operation quicker, safer, and more effective.

· Damage recovery

Many dry goods are carried in bulky, easily torn sacks, like flour or sugar. It is challenging to remove a ripped product from the bottom of a pallet without re-stacking the entire cargo.

Pallet inverters turn the stack to make it simple to remove the damaged goods. Early removal of the damaged products stops a mess from growing as pallets are moved or shipped.

If dry ingredients are kept in storage for an extended period of time without being rotated, they may pack firmly and cake. You can spin dry goods effectively with inverter equipment instead of spending time manually turning products.

· Product orientation

They must alter the orientation of all their products for some customer applications in order to continue processing it. Among these applications are:

- Printing

- Steel stamping

- Corrugated

- Plastic sheet.

If you are interested to know about new designs of pallet inverters atTop Industries Inc. you can see official YouTube videos.