Do you have a particular fabrication or extrusion need? Are you wondering which metal you should use to complete your project? Well, aluminium metal fabrication may be the best solution that you are looking for to get the project done right and on budget.

Unlike other commonly used metals such as steel or iron, aluminium offers a wide range of benefits that you will love. The truth is that there are reasons why so many companies out there choose this material over the other available options.

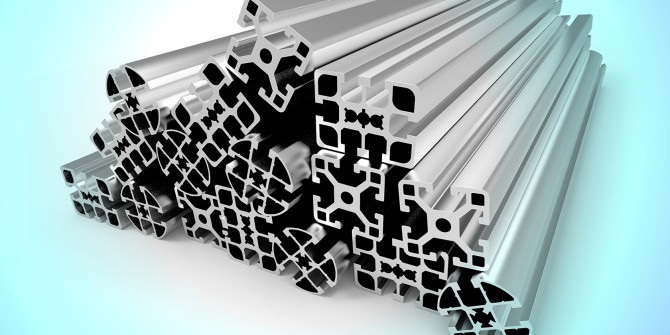

In fact, the more you learn about aluminium and adopt its use in your fabrication and extrusion projects, the more you will see why it is a top choice of many product and parts development manufacturers globally. Here are some of the top benefits of using aluminium for extrusion and fabrication.

Highly Affordable

As far as metallic materials go, aluminium is the most affordable because it can be recycled over and over. Aluminium is also easy to extract compared to other metals, which help to keep the costs down and make it material for use in a large building and metal fabrication jobs.

The billets of aluminium used in the creation of custom aluminium products are also cost-effective. Thanks to the raised awareness and incentive programs for recycling aluminium cans and other aluminium materials, the metal is currently the most recycled material in the world.

Strong and Light-Weight

One of the most exciting benefits of various aluminium products is that they are both strong and light-weight at the same time. This unique property of aluminium metal makes it the most commonly used metal for extrusion and fabrication and for creating parts of boats, automobiles, and even aircraft.

Aluminium has become the go-to material for many car manufacturers since it increases fuel economy for vehicles, and it is also environmental-friendly. Aluminium fabrication experts such as Edmo say that this property also allows for beautiful, airy designs that feature a clean and modern look.

Durable

In the past, steel was the most commonly used metal in building and construction due to its strength.Today, a significant number of structures that were constructed using steel are experiencing severe corrosion, and some of them have already collapsed. Corrosion weakens the strength of steel, making the structure unsafe.

However, aluminium is naturally resistant to corrosion because when it oxidizes, it creates a harder exterior layer of aluminium oxide that protects the metal underneath. This makes it ideal for use in the construction of functional and durable structures such as bridges.

Eco-Friendly

Since aluminium is recycled so much, it is friendly to the environment. Some of its other properties, such as being non-corrosive, strong, and lightweight, makes it a top choice for use in the construction and manufacturing industries.

Aluminium is used in creating cars that get better gas mileage compared to other vehicles made from heavy steel and other metals. Architects and designers working on getting rebates of certification for using eco-friendly materials prefer aluminium because it is readily available and affordable. Typically, there is no end to the number of times that you can recycle aluminium.